Kawalan Suhu Ketepatan, Penyejuk Penyejuk Air Gelung Tertutup untuk Penyejukan Pengeluaran Hidrogen dalam Industri Kaca.

Peralatan penyejukan industri dengan kawalan suhu digunakan terutamanya untuk menyediakan media penyejukan suhu rendah yang stabil untuk pelbagai proses pengeluaran perindustrian. Ia amat sesuai untuk proses pengeluaran hidrogen yang sensitif terhadap turun naik suhu dan mempunyai keperluan kualiti air yang ketat.

Perkara No :

BS-15WDLPesanan(MOQ) :

1Bayaran :

EXW/FOB/CIF/FCA/DPU/DDUAsal Produk :

CHINAwarna :

CustomizablePelabuhan Penghantaran :

SHANGHAI/NANJINGMasa Utama :

15Berat badan :

690kg

Penyejuk sejuk air tertutup kawalan suhu yang tepat (-15~35℃) merupakan peralatan penyejukan teras untuk pengeluaran hidrogen dalam industri kaca (seperti pengeluaran hidrogen melalui elektrolisis). Ia boleh mengawal suhu komponen utama seperti sel elektrolitik dan kabinet penerus secara stabil, memastikan kecekapan dan keselamatan pengeluaran hidrogen. Ketepatan kawalan suhu boleh mencapai ±0.1 hingga ±0.5℃, dan ia sesuai untuk keperluan pengeluaran hidrogen berterusan dan berketulenan tinggi dalam industri kaca.

Prinsip Kerja Penyejuk Berbungkus yang Disejukkan dengan Air

Mampatan: Pemampat memampatkan bahan pendingin gas bersuhu rendah dan bertekanan rendah menjadi gas bersuhu tinggi dan bertekanan tinggi, yang memberikan daya penggerak untuk pemindahan haba.

Pemeluwapan: Bahan pendingin bersuhu tinggi dan bertekanan tinggi memasuki kondenser, di mana ia menukar haba dengan air penyejuk luaran (dihamburkan melalui menara penyejuk) dan memeluwap menjadi cecair bertekanan tinggi.

Pendikitan: Bahan pendingin cecair melalui injap pengembangan untuk mengurangkan tekanan dan suhu, membentuk campuran gas-cecair bersuhu rendah dan bertekanan rendah.

Penyejatan: Campuran suhu rendah memasuki penyejat dan menyerap haba daripada air yang beredar dalam gelung tertutup, menyejukkan air ke suhu serendah -15°C. Bahan pendingin kemudiannya menyejat semula menjadi gas dan kembali ke pemampat untuk mengulangi kitaran tersebut.

Peredaran Gelung Tertutup: Air sejuk beredar di dalam saluran paip yang tertutup, bertukar haba hanya dengan penyejat dan peralatan beban tanpa bersentuhan dengan udara luar. Ini memastikan kualiti air bersih dan operasi sistem yang stabil.

Fungsi Perlindungan Keselamatan

Kawalan Suhu Tepat dan Pelarasan Julat Luas

Julat kawalan suhu -15~35℃ memenuhi keperluan suhu bagi proses pengeluaran hidrogen yang berbeza, seperti pemeluwapan suhu rendah dan penyejukan peralatan suhu biasa.

Dilengkapi dengan sistem kawalan pintar PID dan sensor berketepatan tinggi PT100, ketepatan kawalan suhu boleh mencapai ±0.1~±0.5℃, menghalang turun naik suhu daripada menjejaskan kecekapan pengeluaran hidrogen dan ketulenan produk.

Reka Bentuk Gelung Tertutup Memastikan Kestabilan dan Keselamatan

Air yang beredar beroperasi dalam gelung tertutup, menghalang kemasukan udara yang boleh menyebabkan pengoksidaan, penskalaan dan penyumbatan, sekali gus memanjangkan hayat perkhidmatan paip dan peralatan. Ia amat sesuai untuk keperluan kebersihan tinggi dan penyelenggaraan rendah dalam industri kaca.

Reka bentuk ini mengelakkan penyejatan dan pencemaran air, mengurangkan kekerapan pengisian semula air dan kos rawatan air, serta mencegah potensi bahaya keselamatan yang disebabkan oleh pencampuran hidrogen dan udara.

Kecekapan Tinggi, Penjimatan Tenaga dan Pelesapan Haba yang Stabil

Kaedah penyejukan air menawarkan kecekapan pemindahan haba yang jauh lebih tinggi berbanding sistem penyejukan udara, menjadikannya sesuai untuk operasi pengeluaran hidrogen berkuasa tinggi yang berterusan dalam industri kaca, dengan nisbah kecekapan tenaga komprehensif (COP) yang lebih tinggi.

Ia boleh dilengkapi dengan pemampat inverter dan modul pemulihan haba untuk melaraskan secara dinamik mengikut beban haba, menjimatkan lebih daripada 30% tenaga dan memenuhi keperluan "karbon berganda".

Perlindungan Keselamatan dan Operasi & Penyelenggaraan Pintar

Ia mempunyai pelbagai fungsi perlindungan seperti perlindungan tekanan tinggi/rendah, perlindungan beban lampau, perlindungan pemotongan air dan penggera keabnormalan suhu, mencegah kegagalan peralatan dan kemalangan keselamatan.

Sokongan untuk protokol komunikasi seperti Modbus-485 membolehkan pemantauan jarak jauh dan rakaman data automatik, sesuai untuk pengurusan automatik kilang kaca.

Soalan Lazim

S1: Apakah komponen utama penyejuk air?

A1: Komponen utama termasuk pemampat, kondenser, penyejat, injap pengembangan, pam air, tangki air dan sistem kawalan, dsb.

S2: Apakah julat suhu dan ketepatan mesin anda?

A2: Kami menyediakan penyelesaian meliputi -80°C hingga +350°C, dengan ketepatan kawalan suhu sehingga ±0.5°C, bergantung pada model.

S3: Dalam industri manakah sistem kawalan suhu anda digunakan?

A3: Peralatan kami digunakan secara meluas dalam pengacuan plastik, die-casting, pemprosesan kimia, farmaseutikal, percetakan dan pembuatan elektronik. Jika anda berkongsi butiran proses anda, kami akan memadankan model yang paling sesuai untuk anda.

Model Dan Parameter Teknikal

| Model | Unit | 03WS | 05WS | 08WS | 10WD | 12WS | 15WD |

| Julat kawalan suhu | Suhu air masuk 7-25℃ | ||||||

| Ketepatan suhu | PID±1℃ | ||||||

| Kuasa | AC3Φ380V 50HZ 3P+E(5M) | ||||||

| Medium pemindahan haba | Air | ||||||

| Kaedah penyejukan | Penyejukan tidak langsung | ||||||

| Kapasiti penyejukan | KW | 9.2 | 15.3 | 24.6 | 32.5 | 37.6 | 48.5 |

| Kuasa pam | HP | 0.5 | 1 | 2 | 3 | 5 | 7.5 |

| Aliran pam maksimum | L/min | 95 | 165 | 236 | 315 | 385 | 415 |

| Tekanan pam maksimum | Bar | 2 | 2.2 | 2.4 | 2.6 | 2.8 | 3 |

| Kuasa Pam | KW | 0.55 | 0.55 | 1.1 | 1.5 | 1.5 | 1.5 |

| Penyejat (Aliran Air) | m³/j | 2 | 3 | 5 | 6 | 7 | 9 |

| Isipadu Tangki | L | 55 | 75 | 150 | 150 | 150 | 200 |

| Dimensi (mm) | L | 900 | 900 | 1300 | 1300 | 1450 | 1450 |

| W | 650 | 650 | 800 | 800 | 900 | 900 | |

| H | 1300 | 1300 | 1500 | 1500 | 1550 | 1550 | |

| Berat | kg | 150 | 220 | 310 | 360 | 450 | 650 |

Nota: Spesifikasi boleh berubah disebabkan oleh penambahbaikan produk tanpa notis terlebih dahulu.

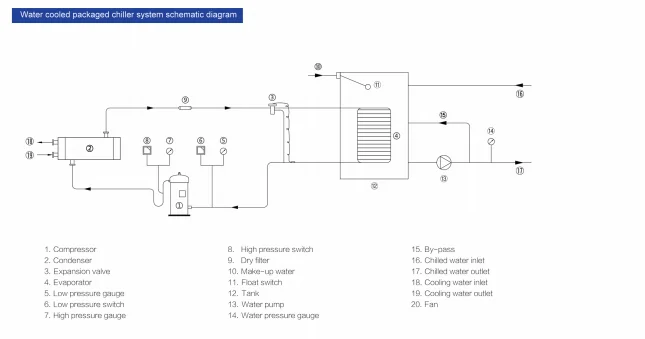

Gambarajah Aliran Proses

Kes Permohonan

Unit kawalan suhu minyak kami digunakan secara meluas dalam pelbagai aplikasi perindustrian, termasuk acuan tuangan, pemvulkanan getah, kawalan suhu roda, teknologi tekan panas, pengeluaran gentian karbon dan tindak balas kimia. Ia memastikan pengurusan suhu yang tepat, meningkatkan kecekapan pengeluaran dan kualiti produk dalam proses ini.

Rakan Kongsi Kami

Penyelesaian Tersuai untuk Perniagaan Anda, Hubungi Kami Cepat!

Tinggalkan Mesej

Scan to Wechat/Whatsapp :